Highlights

- Orexplore has developed a nuggety gold detection system that is being validated through commercial testing with multiple tier-1 gold mining companies.

- The technology seeks to improve the sampling and estimation of nuggety gold deposits and help optimise mine and plant designs to improve gold extraction.

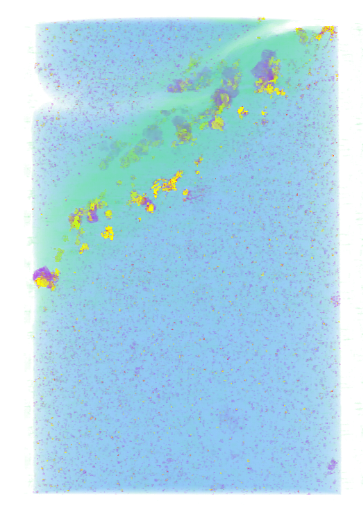

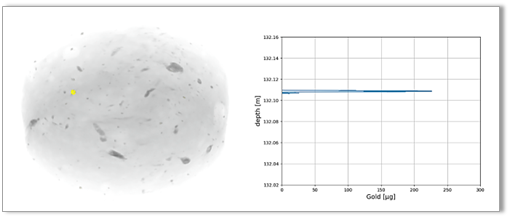

- The system identifies gold nuggets larger than ~100 micrometres throughout the entire core, providing data to support improved operational grade control and to assist in producing more useful estimates of gold mineralisation.

- The technology characterises nuggety gold within 20 minutes on-site, dramatically reducing result times and seeks to optimise the traditional process of sample collection, transport, preparation and analysis through laboratories.

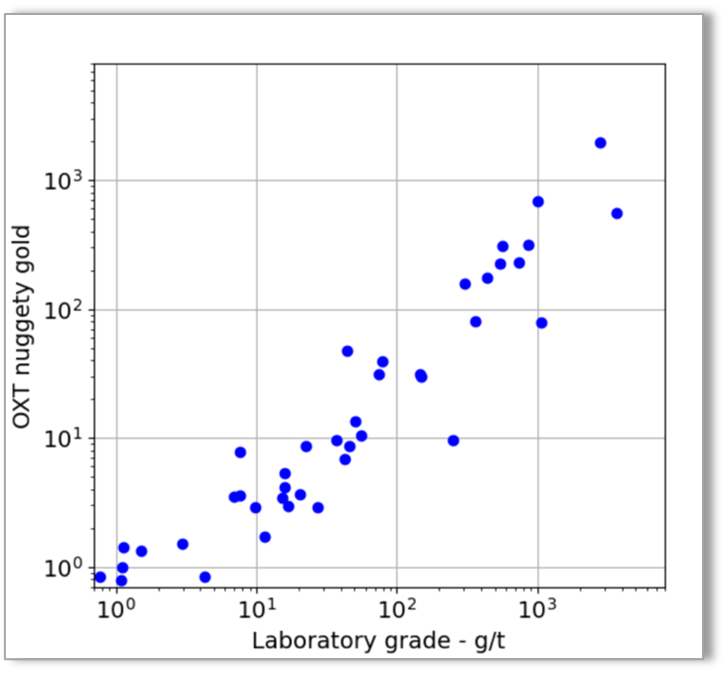

- Validation testing is demonstrating the speed and accuracy of the technology’s site-based nuggety grade results in comparison to current sampling and laboratory processes.

- With gold companies producing more than 17 million metres of core in Orexplore’s current markets (Australia and Latin America) in 2024*1, the market growth potential is significant.

Orexplore’s new technology detects nuggety gold on-site within 20 minutes at the core farm, up-stream of traditional sampling and laboratory processes, optimising the volumes of processed and transported core samples to laboratories which can take up to weeks or even months to provide results. It seeks to reduce the required drill sample volumes and can potentially accelerate the utilisation of OXT gold grades for operational grade control and improved nuggety deposit characterisation.

The new gold detection system rapidly identifies nuggets larger than ~100 micrometres in size throughout the full 3D volume of the core.

Challenges of Nuggety Gold Mines

Nuggety gold mines are notoriously difficult to find, design and operate, yet remain potentially highly valuable if well developed and operated. Technology such as Orexplore’s new system can play a part in assisting this value identification and potential improved capture.

Gold grade may on average be low, due to mineralisation in these deposits potentially being concentrated in spatially sparse “lodes” that have very high local grades, making it challenging to sample efficiently and effectively.

Not only is there a “nugget effect” (where two identical ½ core samples from the same core will produce very different sample grades), the grades themselves may also range from exceptionally high values to zero. This can potentially compromise the estimates of the contained in-situ gold. In addition, designing and operating a mine and process plant that is tailored to the orebody is challenging given this uncertainty in the characteristics of the gold.

The OXT approach presents an opportunity to analyse coarse gold in its natural state without the need for cutting and subsampling within minutes of its digitisation on site. Additionally, because the core is not crushed, the contained gold particles can be characterised along with the minerals and structures that they are associated with in three dimensions.

This provides SMEs in the mining industry the ability to generate a far deeper understanding of the character of gold mineralisation, with a view to improving drill targeting upstream and operational grade control and resource estimation downstream. This rich information suite may also improve the fit between gold in the deposit and the associated mine and processing plant design, seeking to improve the orebody knowledge and extraction performance of nuggety gold mines.

Orexplore’s Managing Director, Brett Giroud, commented:

“Gold mining faces increasingly challenging operating conditions, with nuggety gold deposits possibly being one of the hardest to find, mine and operate successfully. We think there is a great opportunity to help this sector of the industry with the deployment of new technology such as Orexplore’s GX10® system.”

“As a full-core digitisation technology, we can characterise nuggety gold mineralisation within minutes at the core farm. These data streams can potentially support rapid site-based operational grade control processes and improve the gold characterisation to help unlock the value tied up in typically higher-risk nuggety gold deposits.”

“Orexplore is seeing promising initial commercial testing results and external validation of our technology compared to traditional laboratory processes and time for some of our major tier-1 gold mining customers.”

“The market opportunity is large, and the global trend towards unlocking Orebody Knowledge and project techno-economics “closer to the rig” is intensifying as miners seek to optimise their operations and resource development. This nuggety gold characterisation capability at the core farm is another step towards rapid field-sensed Orebody knowledge, and further establishes Orexplore as an important partner in achieving this transformation with its customers.”

Encouraging Initial results from commercial validation testing

Multiple tier-1 gold mining companies are currently testing the technology to confirm its effectiveness, specifically focusing on comparing OXT nuggety grade results with those from conventional laboratory methods and balancing this with the very rapid speed of results, and new value derived from co-located minerals and structures within the core.

Initial testing has been successful, which is leading to increased interest for larger scale commercial laboratory and site-based trials, validating a growing interest in the broader application and benefits of the technology.

Technology applications supporting gold exploration and production.

Orexplore’s GeoCore X10® drill core digitiser is being deployed across the mining value chain in base, precious, and critical minerals and metals mining operations. Key targeted gold mining applications of the new nuggety gold detection system include:

Exploration – supporting gold miners to improve targeting in exploration campaigns and better understand the geological environment, saving time, and reducing costs and resources. Key applications include gold targeting through the improved identification of alteration halos associated with gold, mineralisation style, and mapping of co-located structural and other controls on mineralisation.

Mine and Process Design – improving gold miner’s assessments of coarse gold orebodies to efficiently and effectively mine and extract gold. Armed with the information from the technology, mining companies can potentially improve their modelling and planning of

material flows and match these to the best fit suite of technologies. This approach to matching and synchronising mining and treatment options to in-depth ore body knowledge potentially can improve financial and environmental outcomes.

Production – unlocking the ability for gold miners to quickly estimate the nuggety gold content in ore samples and make informed decisions on where to focus mining efforts. The new system can potentially streamline traditional production sampling processes and enhance grade control, thereby helping to optimise production through all stages of the mining life cycle – from commissioning through to responsible closure.

Market for gold detection technology

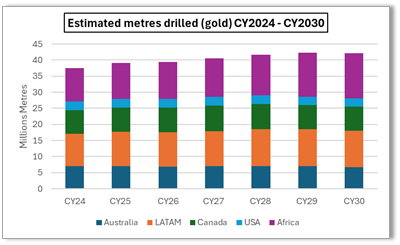

The figure below portrays the estimated metres of drilled core by gold mining & exploration companies CY2024 to CY2030. Estimates show increased drilling activity in Latin America (LATAM) and Africa, stable or minor fluctuations in Australia and Canada, and a slight decline in the USA.

Source: Minex report – Orexplore Prospectus 22 November 2021 – Annexure C – “Industry Expert Report – MinEx Consulting – Figure 24 – Note: metres extracted from overall global metres for regions”

In the Australian and LATAM markets, where Orexplore currently operates, there is an estimated increase in drilled core meters from 17.1m in CY2024 to 18.0m by CY2030.

Looking ahead to the Company’s near-term strategic target markets, which include the USA, Canada, and Africa, estimates suggest a 15% growth in drilled core meters, increasing from 20.5 million meters in CY2024 to 24 million meters by CY2030.